Wind Generators Project Page

Disclaimer:

Disclaimer: I assume no liability for what you may see on this page. In the same way that some people should never have any sharp objects, I do not advocate or encourage doing anything shown on this page. With that said, proceed at your own risk and enjoy the show!

CrazyJerry

The Challenge:

- Design a wind generator that generates usable electricity to help keep batteries charged when solar isn't enough.

- Should be accessible from the ground since changes will be inevitable.

- Since I am my own warranty, simplicity and customer support are mandatory!

- Must be of a 12 volt platform (directly or indirectly).

- Finally, it has to be affordable!

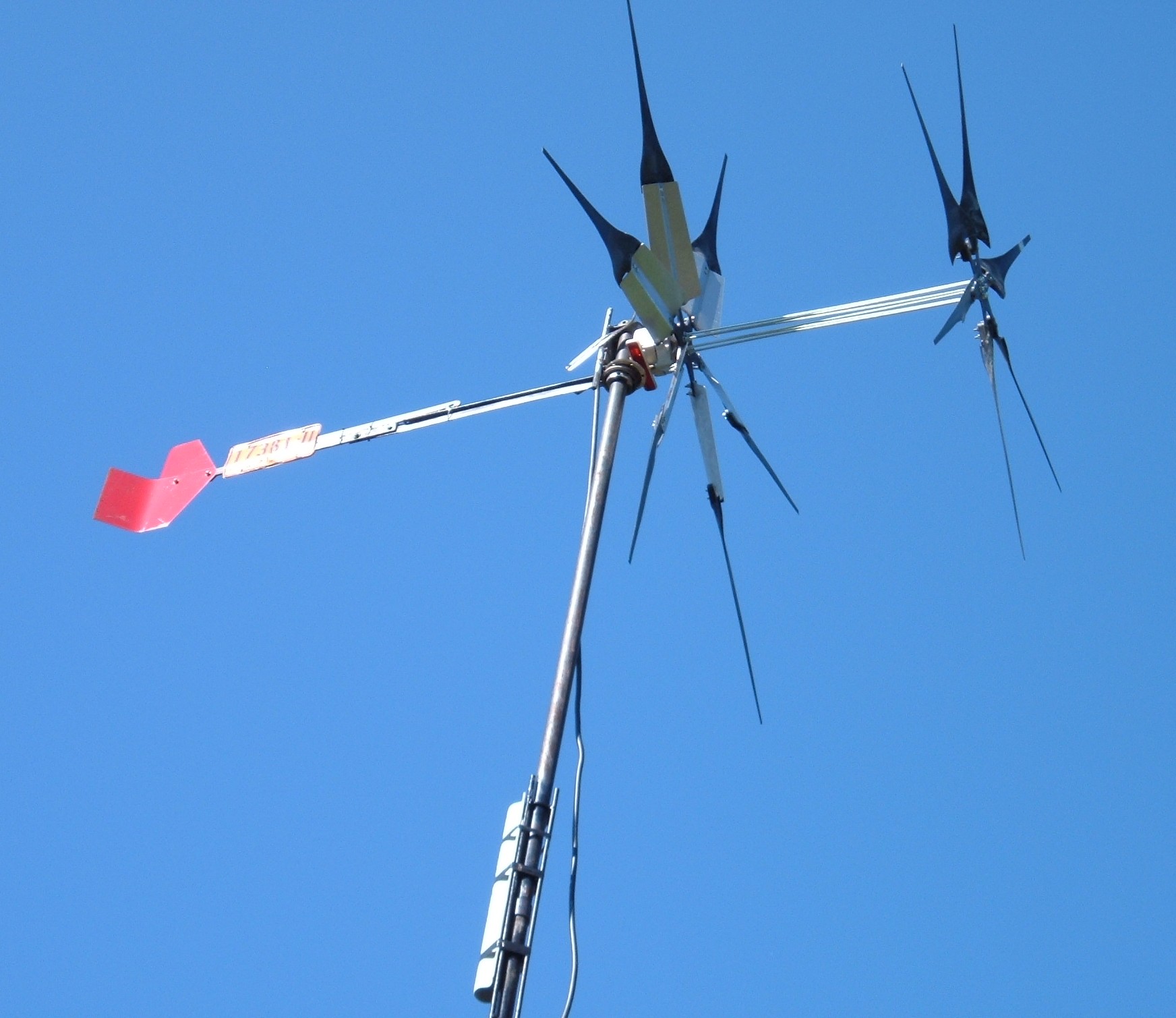

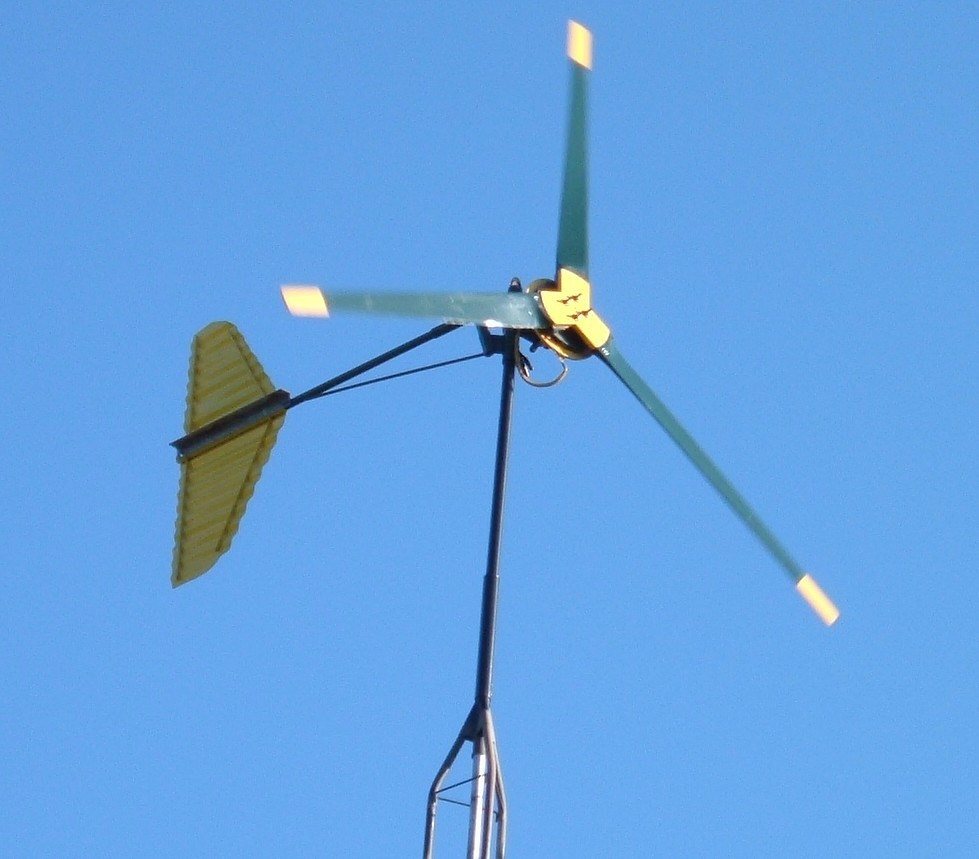

This endeavor wasn't nearly as easy as solar panels are. With a very limited budget, and a less than ideal wind location, this was challenging for sure! Many different types and configurations were tested over the course of several years. During that time we experienced blade imbalance due to icing in the winter. In addition, wind generators are subject to high stress conditions depending on the speed of the wind, and the varying angles of attack that are thrust into the blades. This can cause abrupt changes to all of the mechanics involved and make regulation of the generator output erratic and challenging to manage. Lastly, wind generators are generally a higher maintenance item since they rely on bearings which require lubrication. The temperature changes in our area can cause condensation with these temperature swings and that can lead to contamination of the lubricants. Add in the dust and grit which can be present in swift moving air, and now an erosion of the blades over time becomes another maintenance item. Below are some examples of wind generator combinations I have thoroughly tested (built and/or modified/etc.)

High Voltage Direct Current Wind Generators:

Three-Phase Alternating Current Wind Genrators:

Usability:

These unit can be bulky but are relatively simple. I've tested a variety of blades (wood 2x6's, 2x4's, fiberglass, aluminum, plastic composite, etc.) as well as a variety of generators (permanent magnet alternator, high voltage dc motor, etc.) All mounting, and furling apparatus, etc, was fabricated. A good wind unit starts at a fairly low wind speed (less than 5 mph). The wooden blades that are created using a twist and taper design work the best. The base of these blades have an angle that tends to cut into the wind whereas the smaller tips that lay a bit flatter in relation to the wind allow for faster high speed rotation. The taper lies in between the distance of thick base of the blades and the thinner outer leading tip.

A wind speed of around five miles per hour will get the units spinning but there's no real usable power at such a low speed. Twelve to fifteen miles per hour is a different story especially if the diameter of the blades is 10 feet or more. A stronger supporting structure such as the wind tower and guy-wires will also need to be stronger with larger diameter blades.

In the fall, very strong gusting wind resulting from weather fronts can pose a problem. In addition the power created by the wind generator is very intermittent - think feast or famine. This makes the regulation of these immense power surges a challenge.

In the winter, ice can be a major issue with blade balancing and stress on the supporting structure. If the ice gets into the spinning parts of the generator, it may disable it from operating. If ice gets into the furling mechanism, the unit may not turn out of the wind and create an overs-peed situation. This condition can be catastrophic if the stresses exceed the limitations of the materials used and the unit will likely fail and be extensively damaged.

In the spring, the strong fronts sweep through our area and all the challenges experienced during the fall season, are mostly the same.

Summer is a wonderful time for the wind generator with one exception - lightning! Normally a wind generator need to be up high enough to capture the prevailing wind and as such, it becomes an attractive target for a lightning strike. Care should be taken to protect the system from lightning. Our solution was to watch the weather and if there is a danger of lightning, completely unhook the wind generator from the system and apply the brake so the blades can only spin very, very, slowly. There are other methods that could also help such as a lightning arrester, surge protection circuit, possibly a type of fast-blow fuse, etc.

Building your own wind generator is an excellent educational experience and there is some self-satisfaction when the project is completed and generating electricity into your system. Unlike solar panels, wind generators can also be very soothing, or very exciting to watch, so there is an appeal there. If you are more interested in the set-it-and-forget it system, stick with solar, but if you want the fun of experimentation and the rewards of a mighty wind generator then go for it!